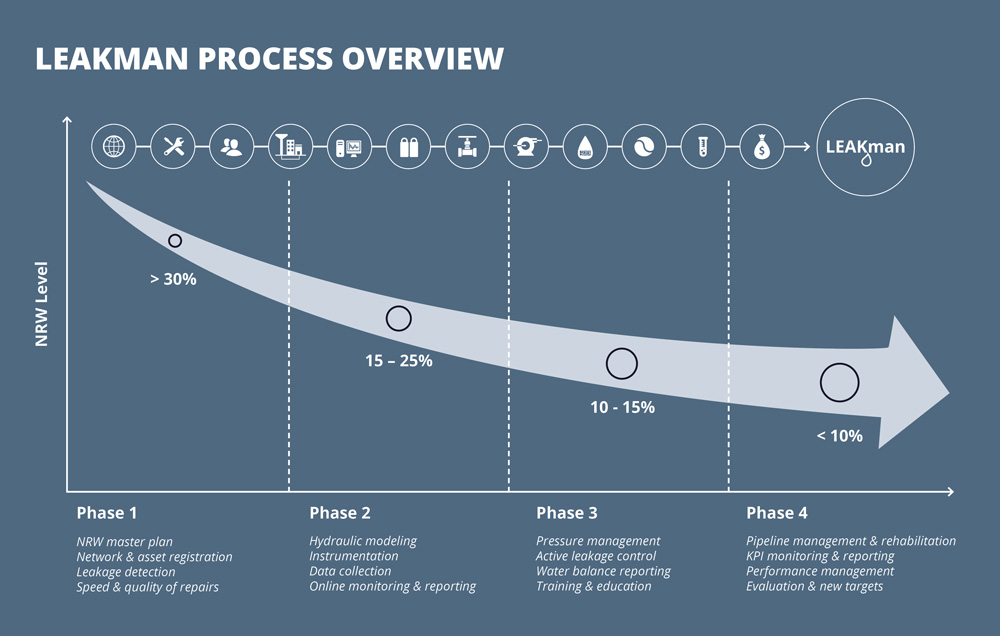

How to get started

Effective and lasting leakage management is not accomplished with a quick fix, and since all utility networks are unique the approach to water loss reduction should be tailored to the specific conditions. No matter what your challenges are, we can help you.

1 Develop an NRW master plan

The first step is to analyse your water distribution system and develop a master plan for NRW reduction. Performing a water audit with a breakdown of the International Water Association (IWA) water balance will help you quantify the different NRW elements to prioritise activities and investments to reduce leakage.

Always consider the full water cycle from the source to the point of consumption. Do not solely focus on the management components of the utility. Customer awareness is also a vital aspect, and every drop counts.

Establish an overview

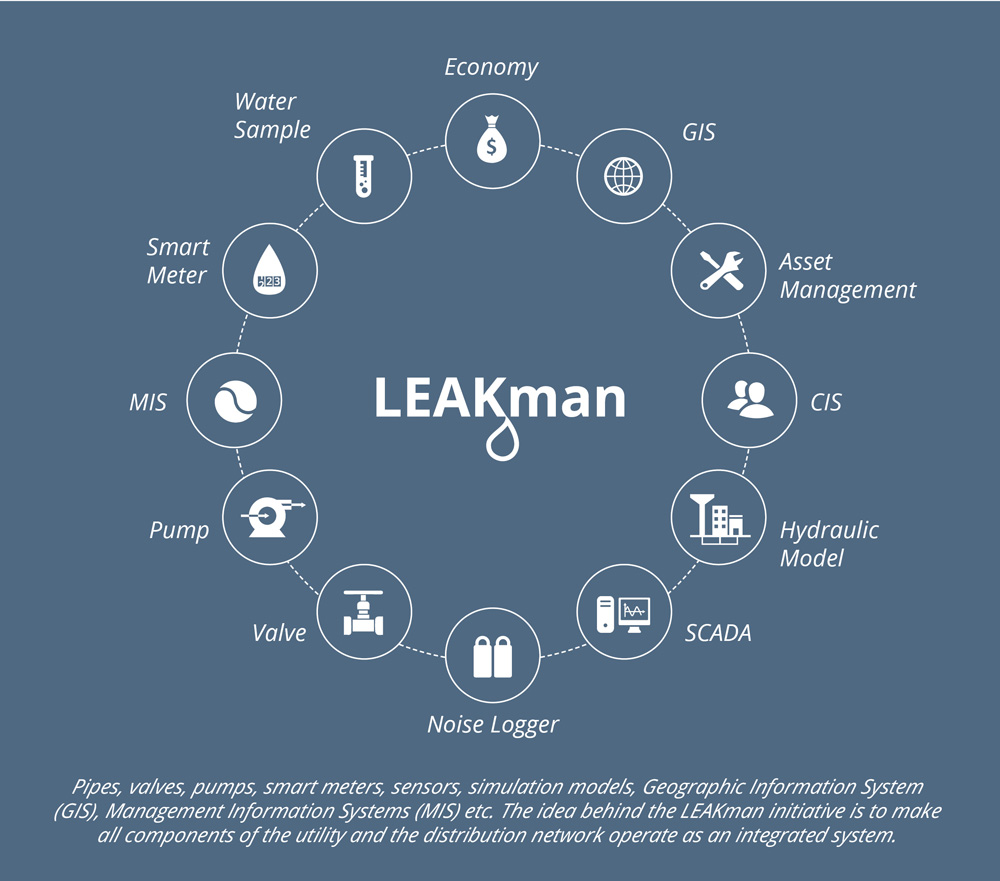

You will need to know your water network in detail. Locate all pipelines, production plants, pumps and valves and register the complete network in a Geographic Information System (GIS) to know exactly where all your assets are located.

You need to locate the major leakages first. Luckily, these are also the easiest to find. Start by using standard portable acoustic equipment and a systematic approach before introducing new high-tech equipment.

Assess and register all identified leakage locations, prioritise and repair accordingly, then store the results in your GIS. At this point, you will have reduced your NRW considerably as well as obtained valuable data about your geographical work area. Building of a historical database of bursts and repairs in the network is essential for the later phases where strategic rehabilitation planning is introduced.

The next steps depend on the current situation at the individual company. First establish an overview, then expand with more advanced systems.

2 Instrumentation and monitoring

Your master plan may have pinpointed the need to investigate basic instrumentation such as intelligent meters (flow, pressure, consumption), gate valves or information communication systems (ICT) such as GIS, CIS (Customer Information System) and SCADA (Supervisory Control and Data Acquisition).

Quality repairs

Skilled and well-trained staff with access to the right tools and equipment is key to persistent leakage reduction. Improving the speed of repair will reduce the volume of water lost through running leaks. However, often it is just as important to focus on increasing the quality of repair to prevent the same leaks from re-appearing shortly after being repaired. An ongoing capacity building programme combined with a few Performance Indicators is vital.

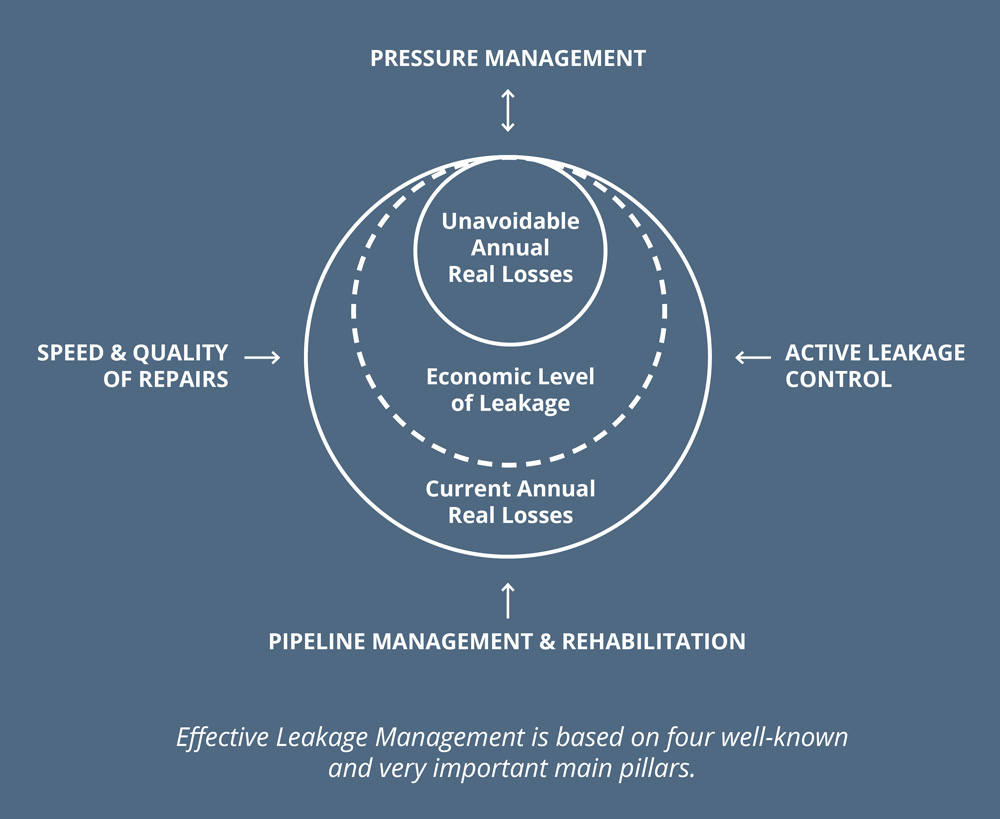

3 Optimizing pressure and leakage control

Intelligent valves and pumps can be utilised to manage the pressure. In combination with hydraulic modelling, pressure management solutions can be designed to operate at the optimal point. The pressure is continuously minimised in the water network on District Metered Area (DMA) level whilst ensuring the minimum required pressure at all customers to maintain a satisfactory service level.

Operating the distribution network at the lowest required pressure reduces not only water losses from existing leaks, but also burst frequency and energy consumption while prolonging the lifetime of the pipes. In other words, it contributes positively to several aspects and thus potentially saves a lot of money.

Using permanently deployed noise loggers reduces the runtime of non-surfacing burst and leaks significantly. Combined with smart meters and short-term water balance reporting on DMAs, it enables the leakage team to react quickly and efficiently and target the weakest areas and pipeline segments.

4 Pipeline management and rehabilitation

Continuous management of the pipeline infrastructure is the only way to reduce leakage to an absolute and lasting minimum. This requires preventive maintenance as well as strategic rehabilitation in order to know when and where to repair or renew. Efficient and logged asset management is a necessary precondition to develop and maintain optimised rehabilitation plans.

Data made available and operational

Objectives should be formulated as a set of (Key) Performance Indicators (KPIs or PIs). Access to updated and validated data is essential in order to select and monitor relevant KPIs. Many utilities are large businesses that generate a huge amount of data; the challenge is to make this data available, operational and visible.

Continuous improved performance

It is vital for any efficient utility company to master performance management. Performance management also contributes to reduce NRW and ensures that the utility executes its primary objectives in the most efficient manner.

Utilities in general have a substantial number of objectives they want to achieve. However, we recommend selecting a maximum of 4-5 essential objectives for a given period typically 1-2 years. As work progresses and objectives are met these may be reassessed and new objectives selected.

We can help

It takes considerable work to get this far. But it is worth the effort. Any utility that are compliant with these standards will achieve a significant reduction in expenditures and a network in good conditions.